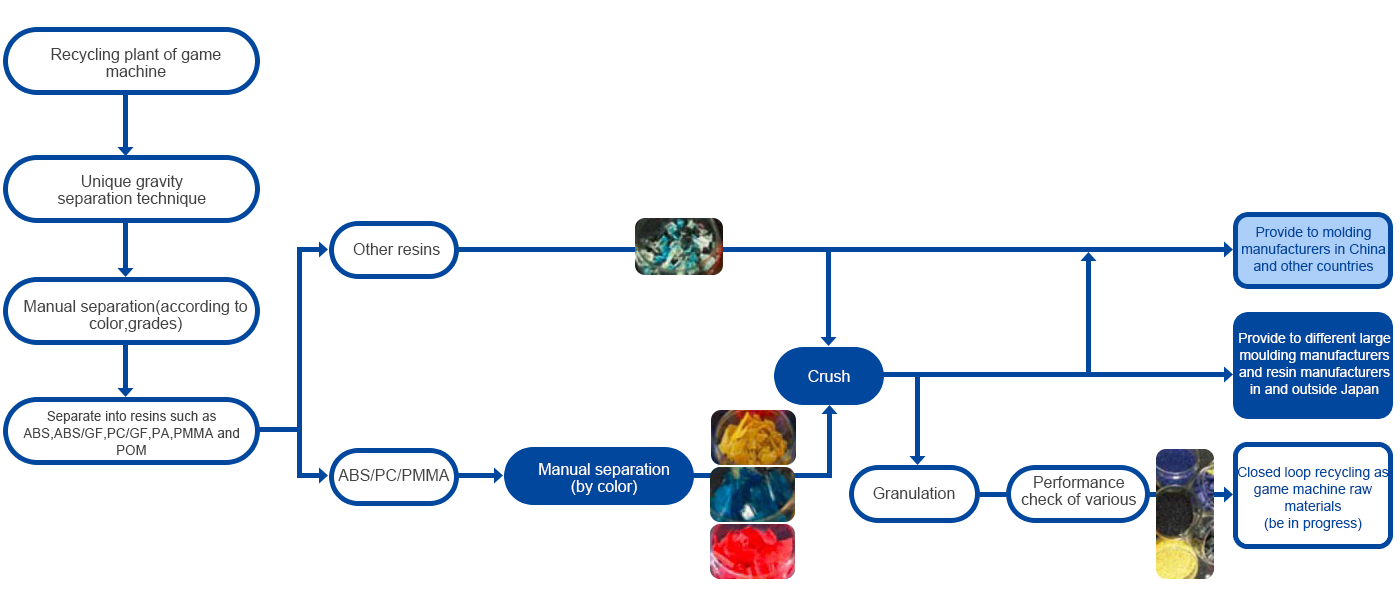

In partnership with a game equipment manufacturing factory, we have developed a model case for international resource recycling. Since mixed waste plastic’s specific gravity exceeds that of water, it could only be burned in the past. However, it can now undergo material separation using our unique gravity separation technique. Therefore, we achieved a high degree of material recycling and established a leading position in this field.

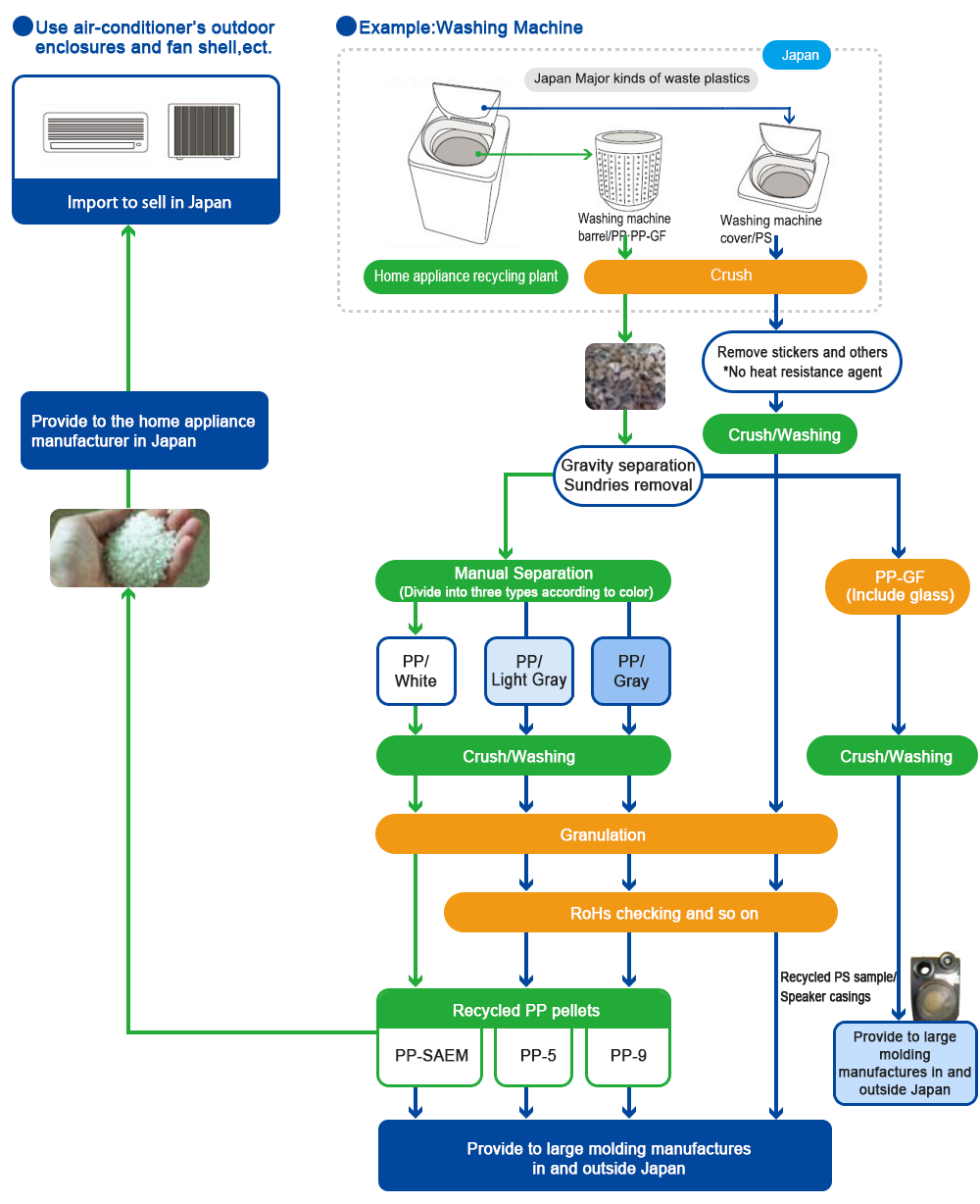

Through our cooperation with an appliance recycling plant, we produced high-quality renewable pellets that meet RoHS standards, thereby achieving closed-loop material recycling in home appliance products. To achieve the above goal, our plants implemented various measures to utilize raw materials, resulting in high recovery and recycling rates of home appliance waste plastics, which significantly contributed to Japanese home appliance recycling.

The first plant in China of our Group(Closed at the end of 2017 by the policy changes of Chinese goverment) mainly does PPC/MFP-associated recycling business for a local Japanese OA machine manufacturer.

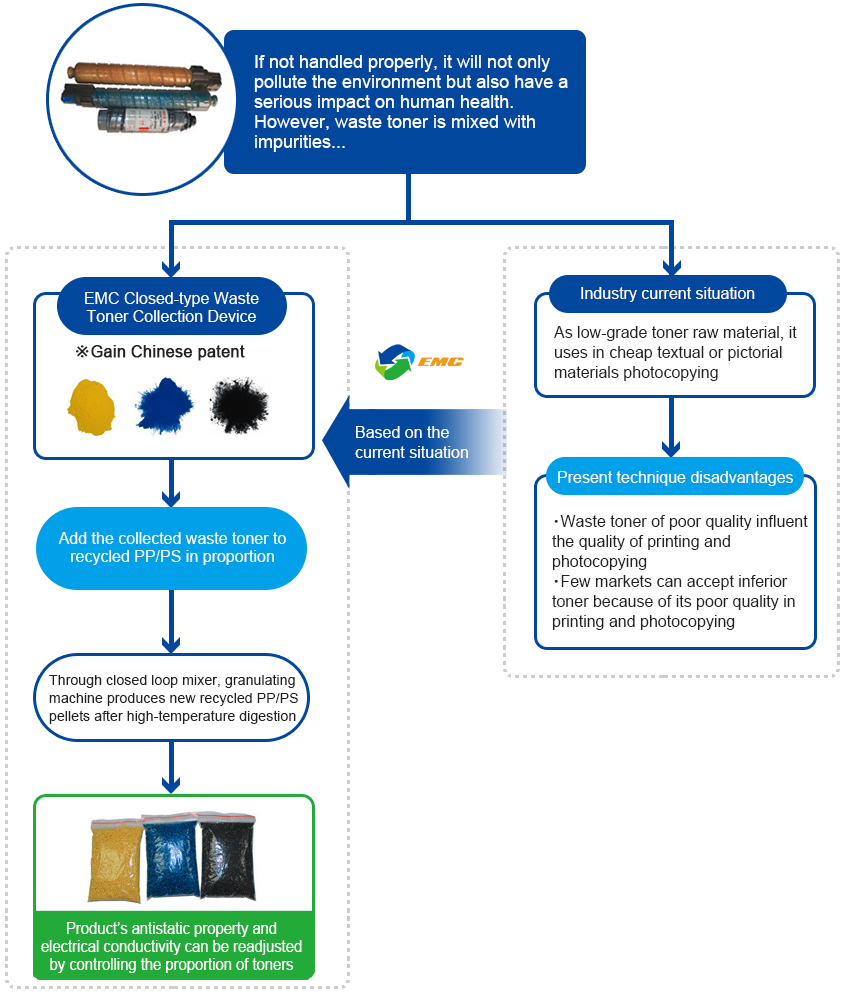

Initially, we discharged the recovery toners in the same manner as other manufacturers, but the recovery rate was relatively low. Therefore, to increase the recycling rate of waste toner, we developed a set of toner recovery machines. The central part of the machine, the toner intake, has gained a Chinese patent.

Through the waste toner recycling device, large quantities of residual toner in out-of-date or waste toner cartridges and toner bottles can be effectively recycled. It can also prevent environmental pollution.

In addition, it improved the antistatic property, glossiness, and black degree of the regenerated PP/PS pellets. This improvement enhances the properties of regenerated products and plays a significant positive role in environmental protection.

Certificate Number: No. 1741582

Patent Number: ZL 2010 2 0268738.3

All of our plants can do the recycled plastic modification.

Modification of waste plastic is the key to developing the green petrochemical industry and the resources circulation industry. Therefore, in 2011~2017, we joined hands with the Chinese South China University of Technology and other universities to set up a new recycled plastic modification R&D center in Guangdong Dongguan, striving to realize world-class quality management and technical research of recycled plastic.

① Waste home appliance plastic/waste TV shell (PS) → Provide regenerated PS pellets to Chinese recorder shell manufacturers, which can be made into about 18 million recorder shells.

② Waste home appliance plastic/washing machine barrel (PP) → Provide regenerated PP pellets to Japanese home appliance manufacturers to produce air conditioners’ outdoor enclosures.

③ OA waste plastic / MEP waste shell, etc. (HIPS, ABS) → Provide regenerated HIPS and ABS pellets to Japanese manufacturers to produce MFP shell.

④ Regenerated container package (other plastic) / high-quality regenerated PP pellets → Regenerated PP pellets for rainwater storage tank and plastic container.

⑤ Regenerated container package (other plastic) / high-quality regenerated PE pellets → Regenerated PE pellets for plastic bags and convenient bags.

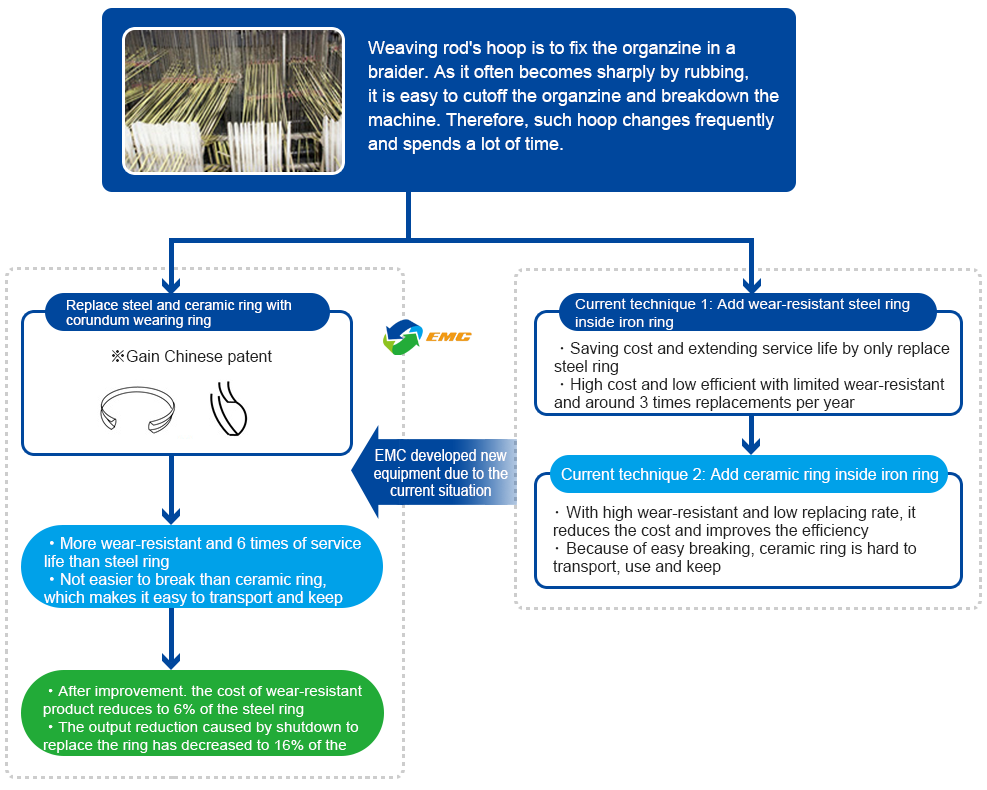

The first plant in China of our Group specializes in manufacturing the raw material for FIBC bags. Its raw material is the recycled material that includes 60% regenerated plastic. Compared to general raw materials, recycled materials increase the machine's burden and are more prone to breaking the braider. Therefore, the heavy wear on braiding parts has become a significant problem that hinders productivity. To solve this problem, we conducted research and made improvements to the braider. After conducting extensive research, we successfully extended the working life of the braider and decreased the breakdown rate.

Above all, due to the anti-abrasion and hardness properties of corundum, the wearing ring made from it greatly extended the service life. Therefore, it helps reduce the changing frequency, decrease cost and time, and improve production efficiency.

At the same time, it also indirectly enhances the effectiveness of using regenerated material. It is conducive to using more regenerated material to manufacture new products, thereby contributing to environmental protection.

Certificate Number: No. 1692894

Patent Number: ZL 2010 2 0268725.6