Eco-Material Corporation is among the top companies in the industry when it comes to the recycling of mixed plastics from home appliances. It is a designated product user of the Container and Packaging Recycling Association, and also a leading company in the material recycling of mixed plastics from office automation equipment, gaming machines, and the like.

Our main business partners include Hitachi, Ricoh, JFE, Toshiba, Mitsubishi Electric, Sony, Panasonic, etc., and we provide one-stop services to our customers.

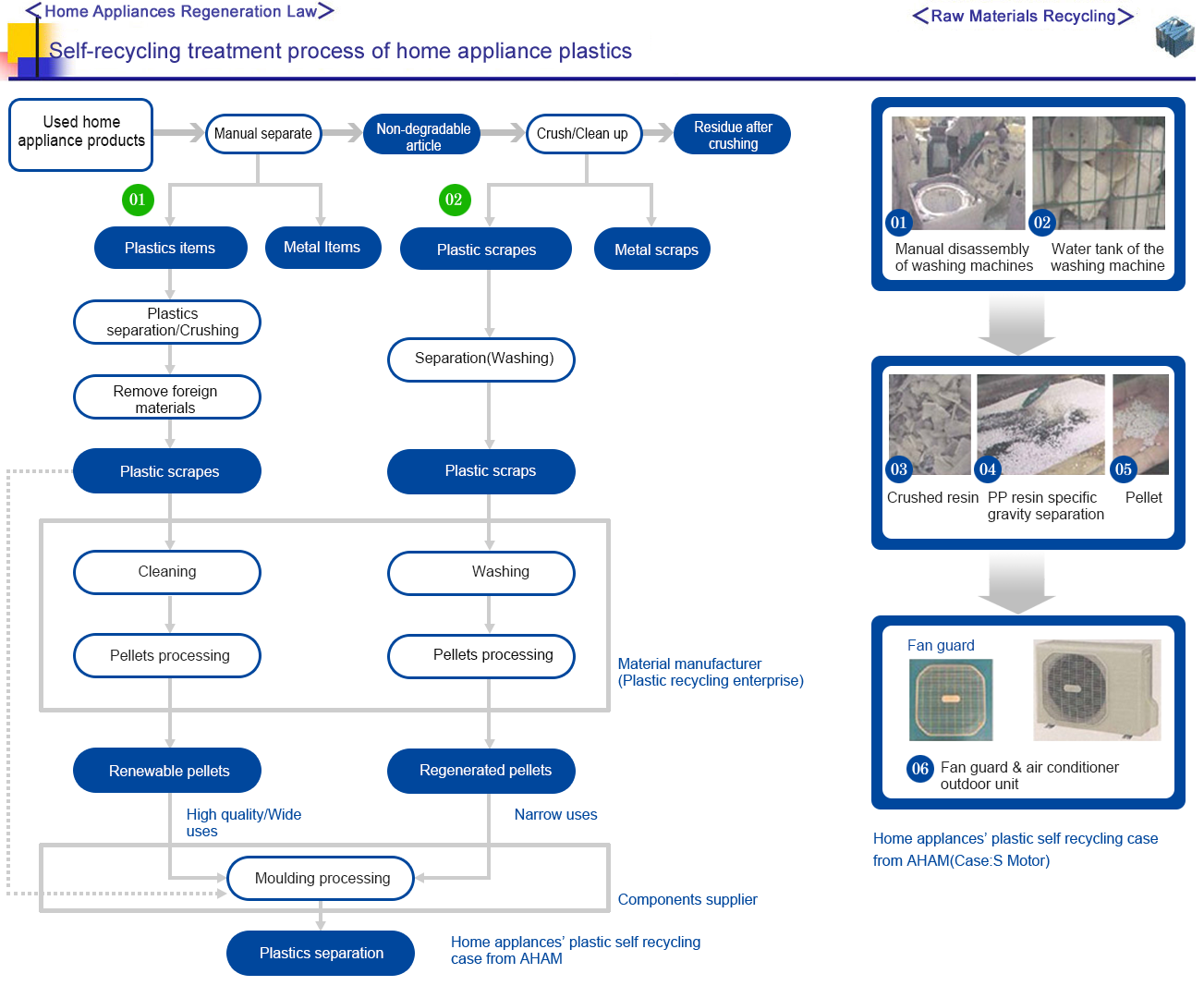

The popularization of household electrical appliance has brought people convenience of life, it also produced quantities of wastes on the other hand. For those household electrical wastes, how to set up a recycling system has become a priority of many countries. In order to reduce home appliance wastes as well as to realize recycling, Japanfirstly launched the Special Home Appliance Equipment Commodification (Home Appliance Recycle Method) in April 2001. By 2011, this method has been implemented for 10years. During these ten years, more than 130 million home appliances has successfully been recycled. Suppose the length of each equipment is one meter, the total lengths of the recycled products can circle the earth 3 times.

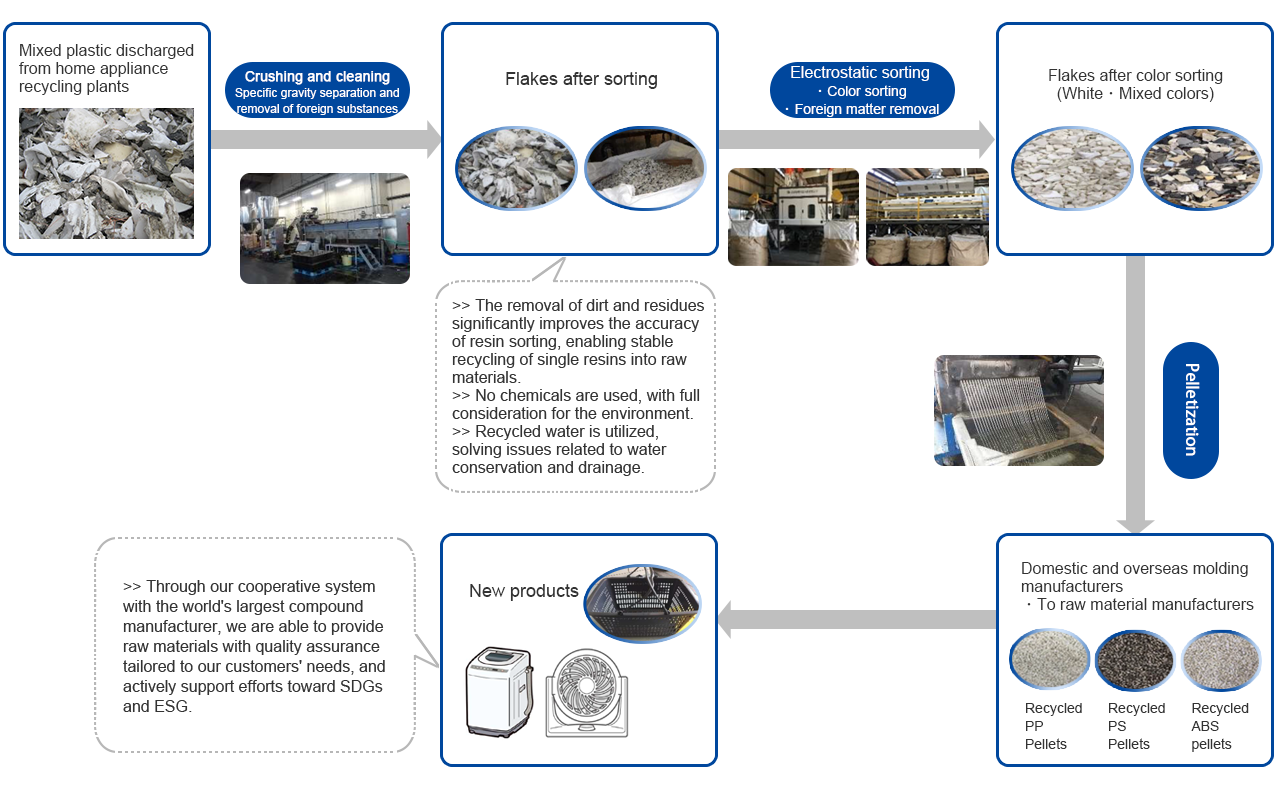

Since 2003, our company has been engaged in the recycling business of waste electrical and electronic plastic. Leveraging our unique sorting expertise and advanced traceability system, we have gained the trust of Group A and Group B of home appliance recycling plants. We promote resource recycling that does not rely on incineration or landfilling both domestically and internationally, and currently, we have achieved a material recycling (MR) rate of over 95%. As a company boasting the top market share in Japan, we are contributing to the realization of a circular society.

By introducing a sorting line that leverages our original recycling technology accumulated over more than 20 years, we have made it possible to stably produce recycled raw materials of single resins from a wide variety of mixed plastics.

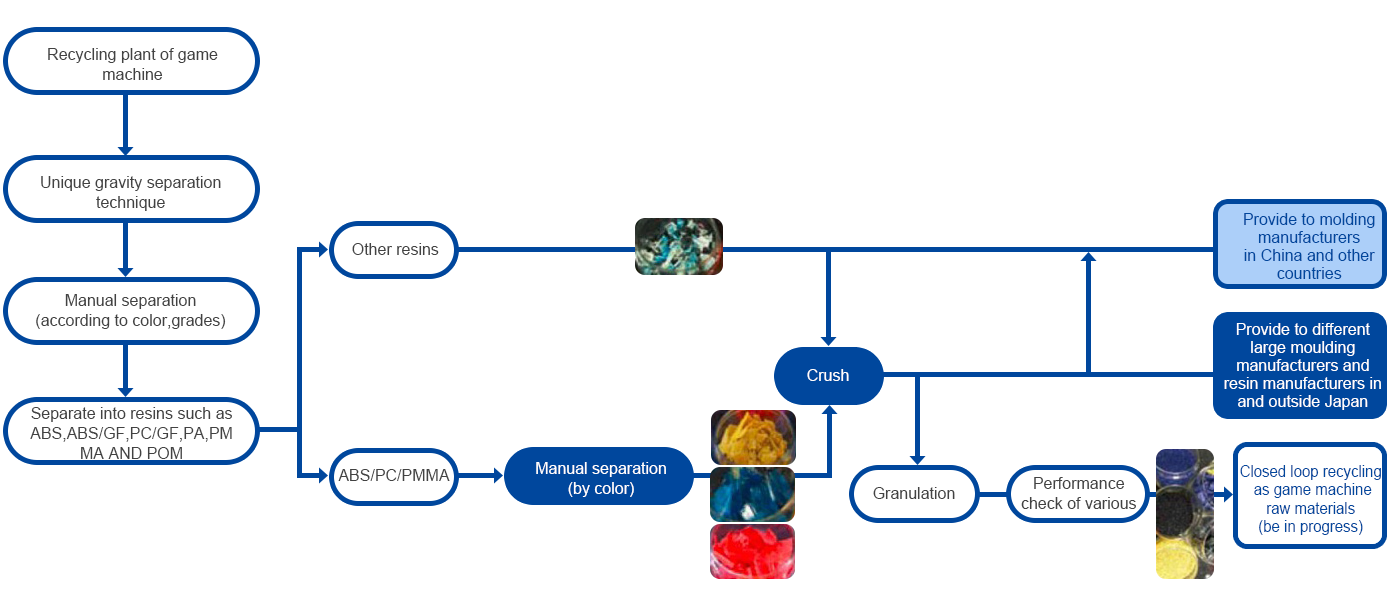

Joining hands with game equipment reproductive factories, we become a model in international resources recycle. As mixed waste plastic’s gravity is greater than water, it could only burn in the past, but now, it is able to do material separation through our unique gravity separation technique. Therefore, we achieved a high degree of material recycling and established a leading position in this field.

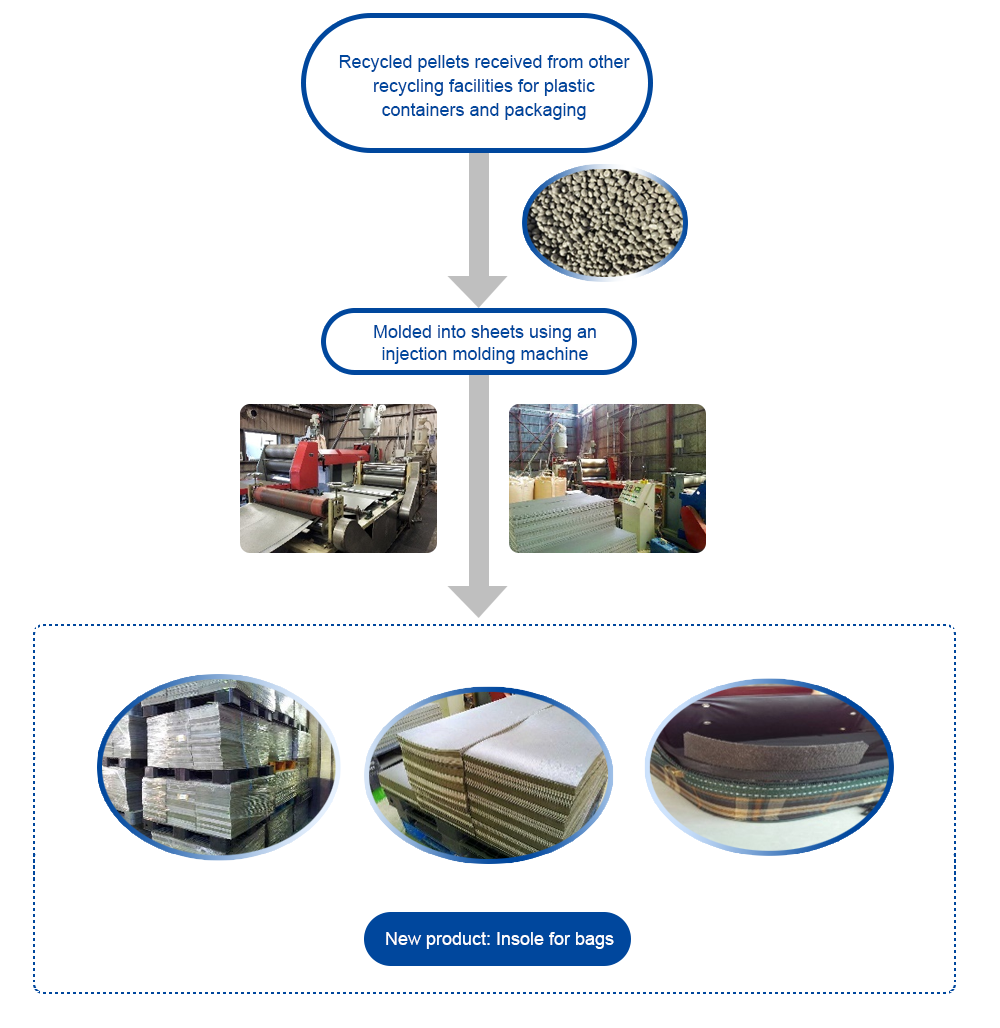

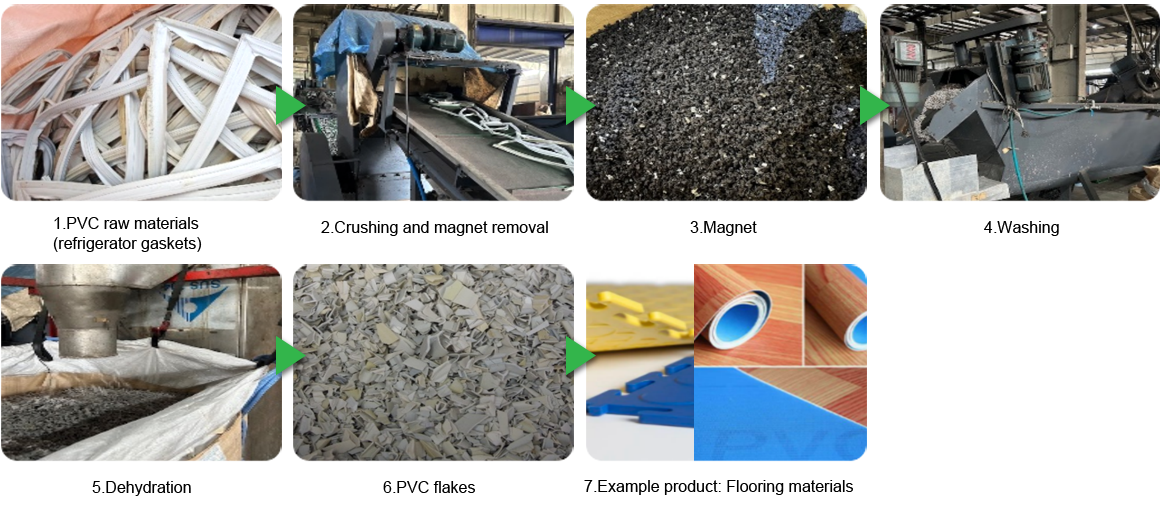

In 1996, with the enforcement of the "Act on Promotion of Sorted Collection and Recycling of Containers and Packaging" (commonly known as the "Container and Packaging Recycling Law"), the recycling of container and packaging waste, including PET bottles, began to be promoted nationwide. Among such waste, PET bottles have a particularly high recycling rate and are regarded as one of the materials that symbolize Japan's environmental policies.

Since our Saitama Head Office Factory was certified as a designated PET bottle recycling plant by the Container and Packaging Recycling Association, we have been engaged in the PET bottle recycling business. We have strived to effectively utilize resources by sorting and cleaning the collected bottles, processing them into flakes, and selling them as raw materials to manufacturers.

Currently, the PET recycling business at our Saitama Head Office Factory has been terminated. However, after reviewing our system, we continue our PET bottle recycling activities by supplying raw materials to reliable PET bottle recyclers.

Meanwhile, we have installed automatic PET bottle collection machines in Annaka City and are working to provide citizen services in collaboration with the city.

In 1996, the "Container and Packaging Recycling Law" (officially known as the "Act on Promotion of Sorted Collection and Recycling of Containers and Packaging") was enacted as a law to promote the recycling of container and packaging waste. The targets include glass, paper containers and packaging, PET bottles, and other plastic containers and packaging.

Since 2011, all four of our factories have been certified as recycling business operators by the Japan Container and Packaging Recycling Association, and we have been engaged in recycling business as a user of recycled products.

Leveraging our compounding technology and application development capabilities accumulated over many years, we are engaged in a business that replaces plastic products made from virgin materials with recycled materials. In this field as well, we adhere to our corporate philosophy of prioritizing "closed-loop recycling" and "horizontal recycling."

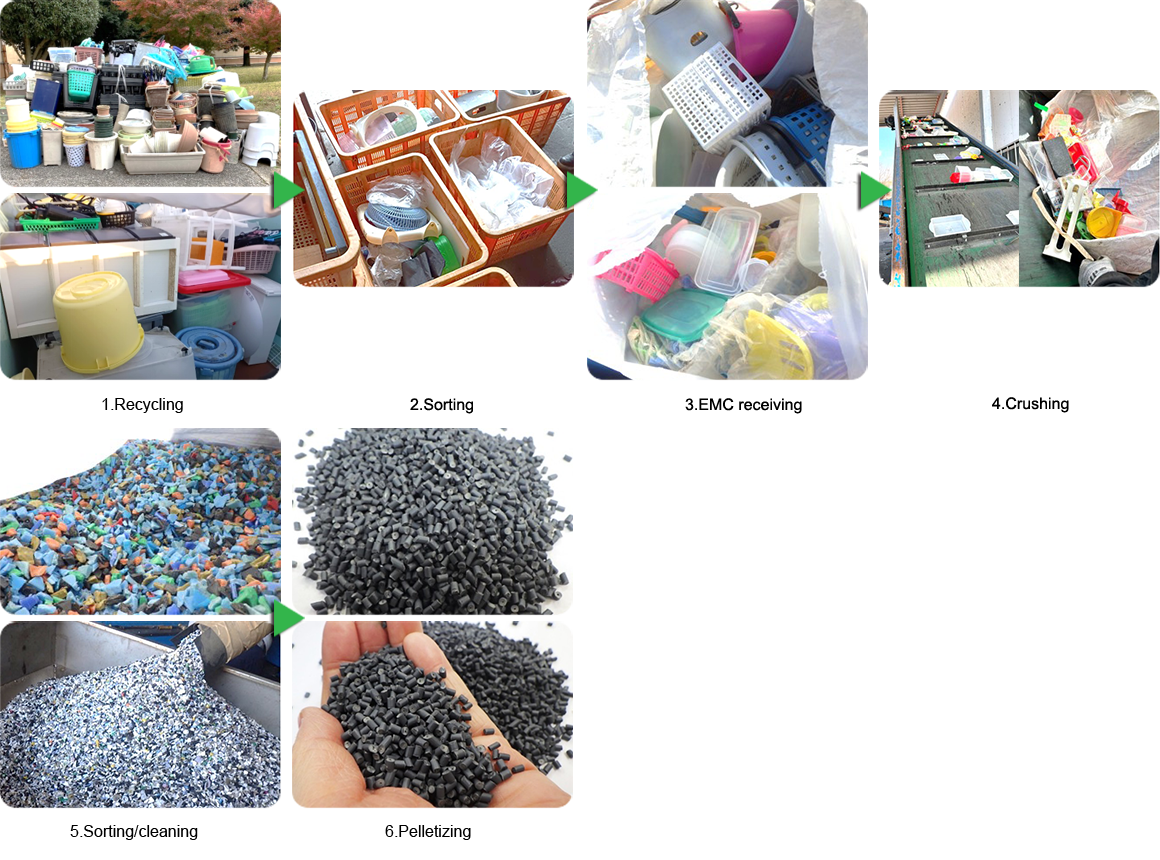

Ecomaterial is also cooperating with local governments to comply with the "Plastic Resource Circulation Promotion Act" enforced in April 2022. In the demonstration test, we have established a process in which we accept product plastics collected and sorted by the administrative authorities, crush, sort, and clean them using our equipment, and then recycle them into pellets by type of resin.

Through this demonstration, a mechanism to utilize plastic products discharged in local communities as new resources has become a reality, marking a step toward the formation of a sustainable circular society.

To this day, we continue to build mechanisms that support regulatory compliance and resource circulation by leveraging these achievements and collaborating with local governments, companies, and communities.

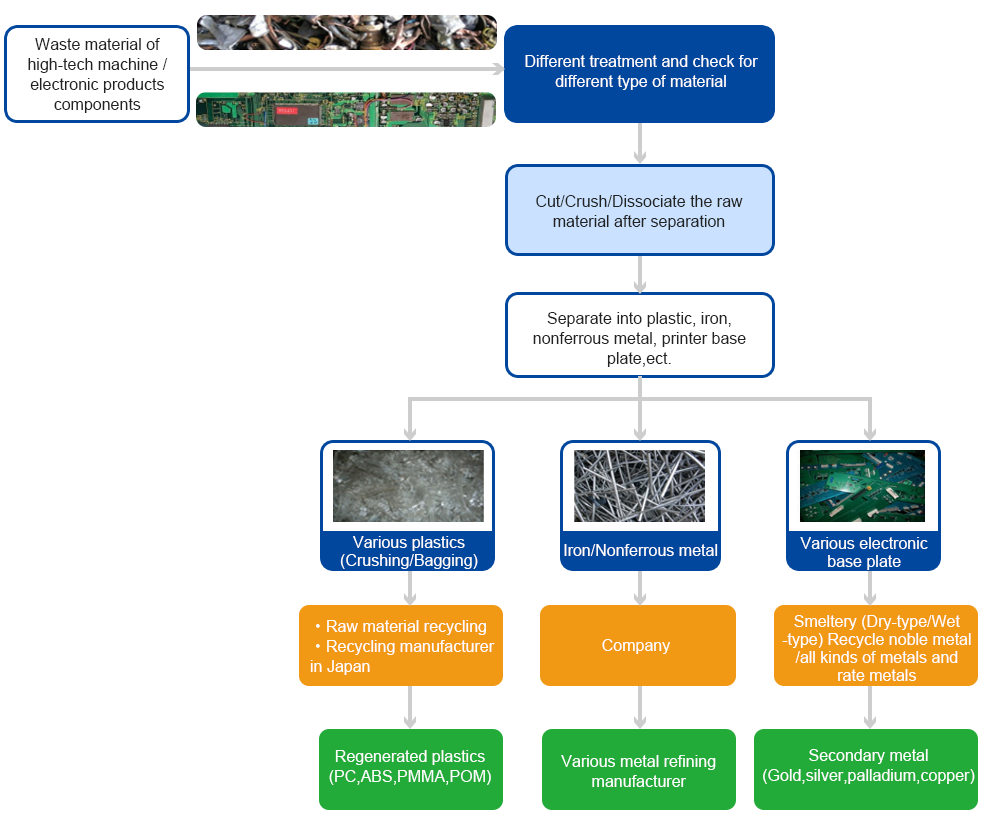

Our company has been engaged in business activities specializing in the material recycling of waste plastics. Tracing the origins of the waste plastics we handle, they come from home appliances, office automation equipment, and amusement equipment. Naturally, these contain a lot of metal, and there are parts that cannot be easily separated from the plastic. In response to requests from customers to manage these [metals and plastics] together in a unified manner, we also handle metal and non-ferrous metal recycling businesses.

New cut workpiece / Leftover materials of a whole piece of metal plate after machine cutting

L-1 / Mainly steel office supplies

Metal scraps / Metal scraps after manufacturing the screw and nut

Tinplate / Tinned sheet iron

CPA / Press flat the iron cans

Copper / Copper No.1 / Copper No.2 / Mine / etc.

Wire cover / CV line / SV line / IV line / Cable / etc.

Brass / Rebar / Cupriferous metal / Bronze valves / etc.

Aluminum / Aluminum can / wheel / etc.

Special metal / New nickel offcut / Tungsten / All kinds of alloy

Rare metal / IC base board / Memory board / CPU / Various gold plating / etc.

Other / Electromotor / Transformer / MIX metal / etc.